Supply Chain Planning

Simulate your supply chain and dynamically adapt your logistics network in a constantly changing environment.

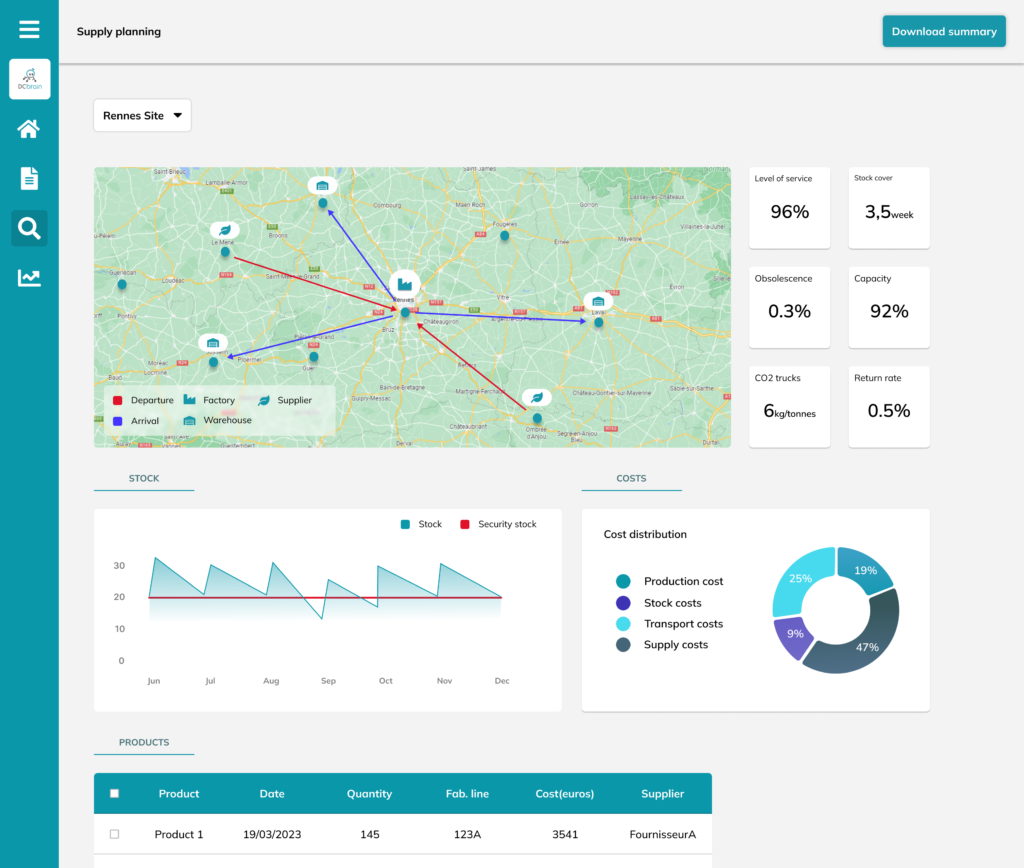

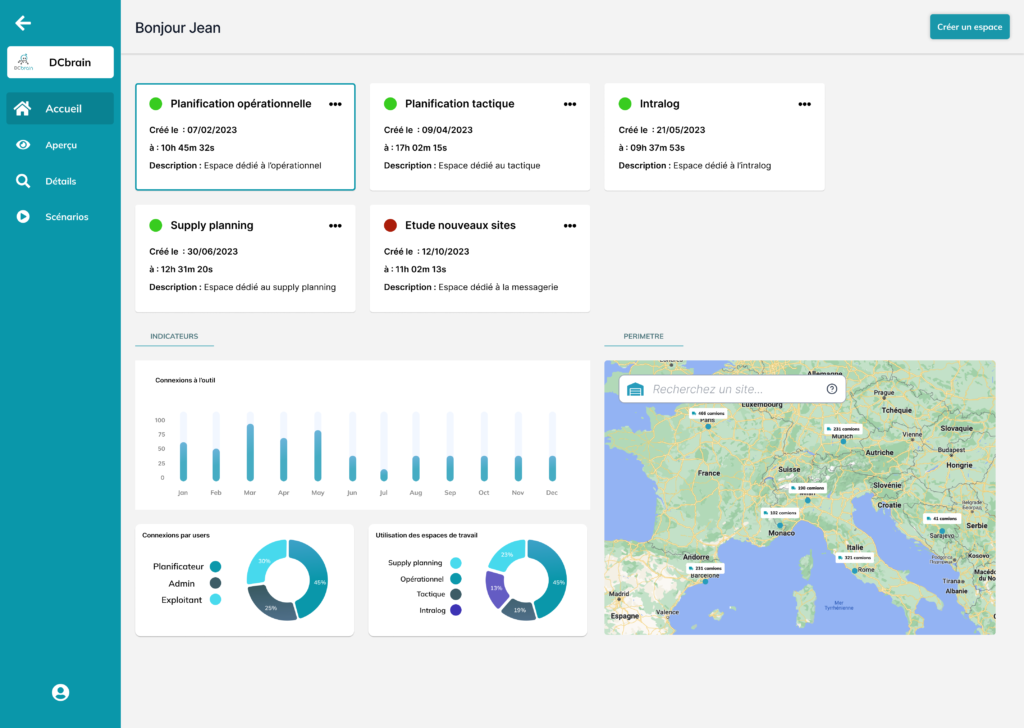

Our solution enables you to perform fine-grained modeling of your global supply network, from suppliers all the way through to end customer delivery points. You can analyze projected flows, stocks and resource use, and use our powerful AI to build an adaptive and sustainable supply chain.

Meet your Supply Chain challenges with our expertise

We have designed the DCbrain solution in collaboration with supply chain managers and planners. The aim is to meet the specific challenges involved in tactical planning of the global supply chain. With our expertise in AI and engagement with our clients, we have developed a powerful, agile and business-oriented solution.

How can we help you?

Prepare for future development needs and secure your resources

We give you the means to clearly analyze your projected resource situation (stock levels, capacity usage). With our dedicated optimisation algorithms, you can formulate your supply strategies (stocks, production versus subcontracting, transportation modes, suppliers) throughout the value chain and assess related costs, as well as the impact on your SLA.

Control the complexity of your network and make informed decisions

Using our digital twin and AI technologies, DCbrain helps you grasp the complexity of your supply network. Our solution provides you with essential analysis tools (what-if scenarios, key indicators, financial information) to make decisions supported by figures and calmly prepare for peak periods or crises.

Achieve your environmental and societal goals

Using our simulation tools and native integration of indicators and environmental performance drivers (including transportation modes, distances travelled and operational CO2 emissions), you can measure and forecast the environmental impact of your decisions. Going a step further, you can also use these indicators as targets to be optimised by our algorithms.

Benefits

Improve your SLA while reducing your costs and carbon footprint

Control your stock levels and secure your supplies

Save time and increase decision-making transparency

Application Examples

Optimisation of a multi-site and multi-level network

- Model the complexity of the global supply chain while taking into account multiple sites, clients, products and alternatives

- Plan volumes to be supplied, produced and distributed at each link in the chain

- Optimise network use to achieve target service levels and minimise costs (stock, transportation, production)

- Recommend the best allocation of clients to distribution or production sites, and of product lines to the various production sites

Scaling of internal and subcontracted production resources

- Model production resources, whether internal or subcontracted, including their specific characteristics, capacities and costs

- Take into account projected demand to plan ahead for maintenance operations, slow periods and peaks of activity

- Choose between various production strategies (2×8, 3×8, subcontracting, stock building) based on impact assessments supported by figures

Determining the best supplier and/or transportation mode

- Determine the best supplier by weighing up risks and costs

- Manage multi-modal transportation flows (air, sea, road) based on fine-grained modeling of specific price conditions, deadlines and supply constraints

- Analyse supply plans and projected stock levels of your raw materials and components, and semi-finished or finished products

They trust us

Ready to get started to boost your Supply Chain?

We are convinced that AI can facilitate logistics planning and will prove it to you via a demo.

Want to know more about engaged AI?

You want to understand how Artificial Intelligence can simplify the daily life of planners and become your ally on your decarbonisation issues.