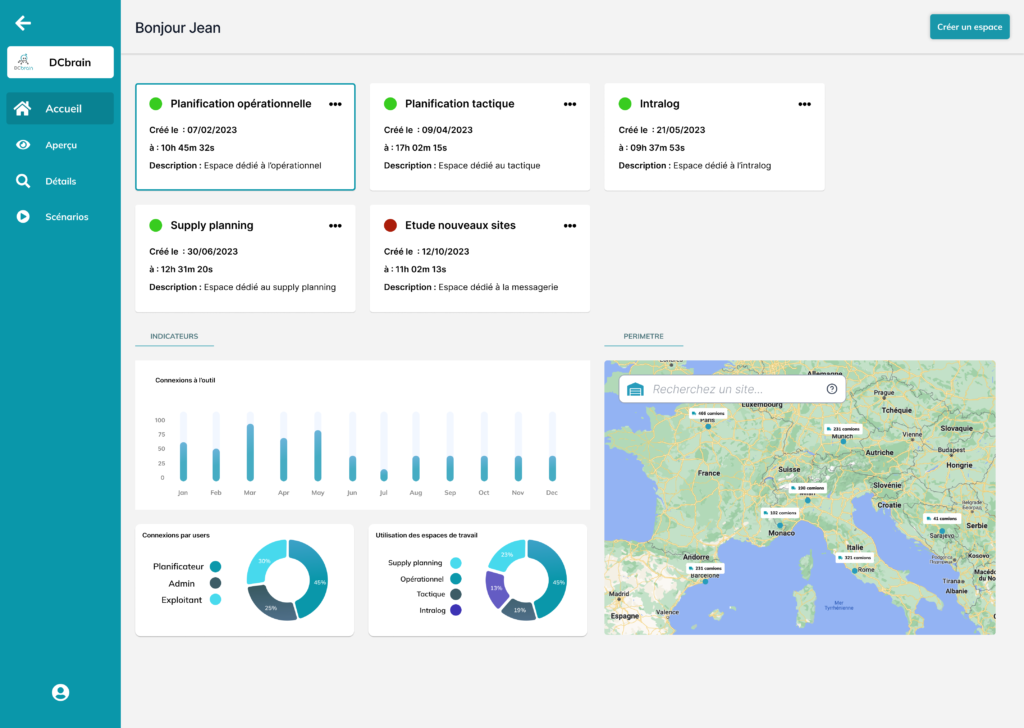

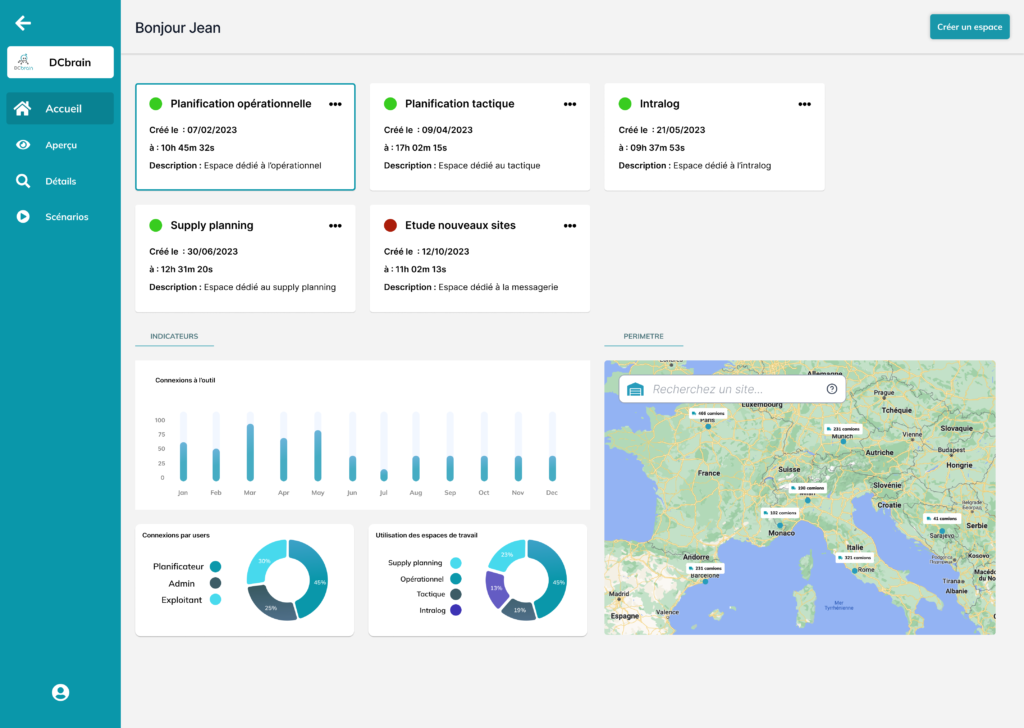

Lidl uses the tactical planning solution to facilitate construction of its transportation plans

Lidl has become a leading French distributor in a short space of time and currently has more than 1500 stores throughout France. With DCbrain, Lidl is meeting its two main challenges: cost optimization and CO2 emissions reduction.

Faced with increased transportation costs and the need to reduce its CO2 emissions, Lidl chose DCbrain to digitalize and optimize its transportation plans.

Devising and updating transportation plans at Lidl is a highly complex matter: 25 warehouses supplying 1580 outlets, with various product typologies. With few tools available for these operations before DCbrain, the chain was unable to meet its economic and environmental objectives.

Our organization is based on a twice-yearly review of all our transportation schedules. Until now, these schedules were created manually as we had no digital tools.

Lidl wants to minimize its transportation costs and reduce its CO2 emissions. Furthermore, the group wants to design its transportation plans in a digitalized, optimized and dynamic way.

The central teams tasked with logistics planning are concerned. Local dispatch teams also use the solution.

Manual updating of transportation plans could only be done infrequently and did not guarantee optimization.

LIDL has made a commitment to reduce its CO2 emissions and this means that we must further optimize our transportation plans. With DCbrain’s AI, we can meet these challenges.

We are convinced that AI can facilitate logistics planning and will prove it to you via a demo.